ABOUT AK-INDUSTRIES

Since its creation in 1998, AK-Industries has specialized in the engineering, development and manufacture of draw wire sensors and rotary encoders for linear and angular displacement measurement.

We quickly realized that each project is as unique as its owner. That’s why, inspired every day by our customers, we design the tailor-made products they need. Always with the same philisophy: to support them before, during and after the start-up of their projects.

Our engineering department and factory are housed on a single site, near Strasbourg, to ensure the best teamwork. Our driving force is the success of your projects!

AK-Industries’ Summer Holidays : we’ll be out of business from August 09 to August 17, 2025 inclusive.

The whole team wishes you a nice summer!

Our values

Listening and availability

At AK-Industries, we believe that every need and every project, whatever it is, has its reason to exist and deserves to be considered carefully.

That’s why we take the time to listen to our prospects and customers, and rise to the challenge of building the most appropriate solution together.

Advice and service

It’s very important for us to offer our customers the best possible support.

Our expertise and wide-ranging feedback enable us to provide technical advice. This ensures the best possible balance between our products and their use in real-life conditions by our customers.

If our customers need technical support, we’re here to find the best solution for them.

Customer satisfaction

By calling on AK-Industries, our customers get the support of a voluntary team that is focused on responding their needs. Both in proposing the right product and offering the best service.

Our aim is to help our customers achieve their goals with complete satisfaction.

Sustainability

We focus on designing robust sensors and encoders for use in harsh environments. However, in the unlikely case of damage caused by hard use, we offer to repair them whenever it’s possible. A cost-effective solution for a long service life!

Raising / lowering of containers

Raising / lowering of containers

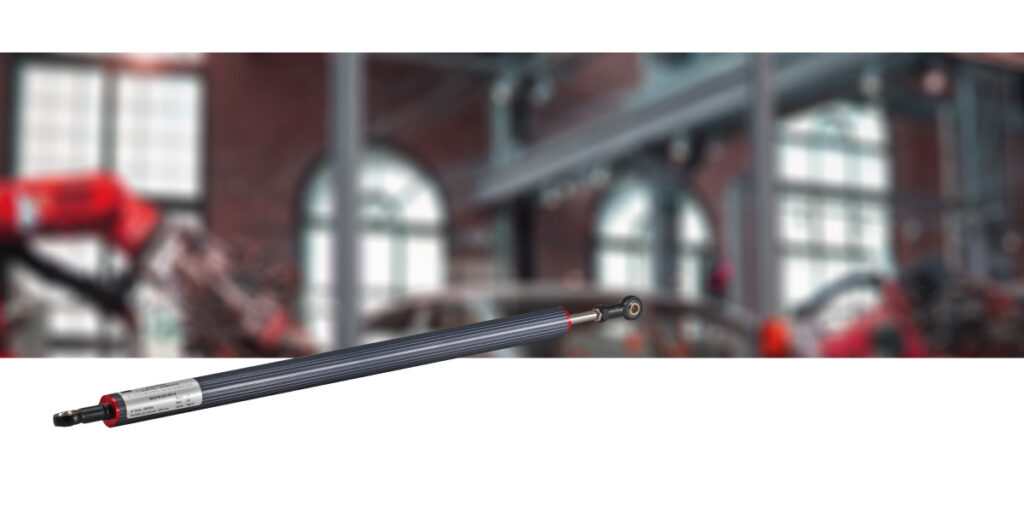

Displacement of hydraulic actuators

Displacement of hydraulic actuators

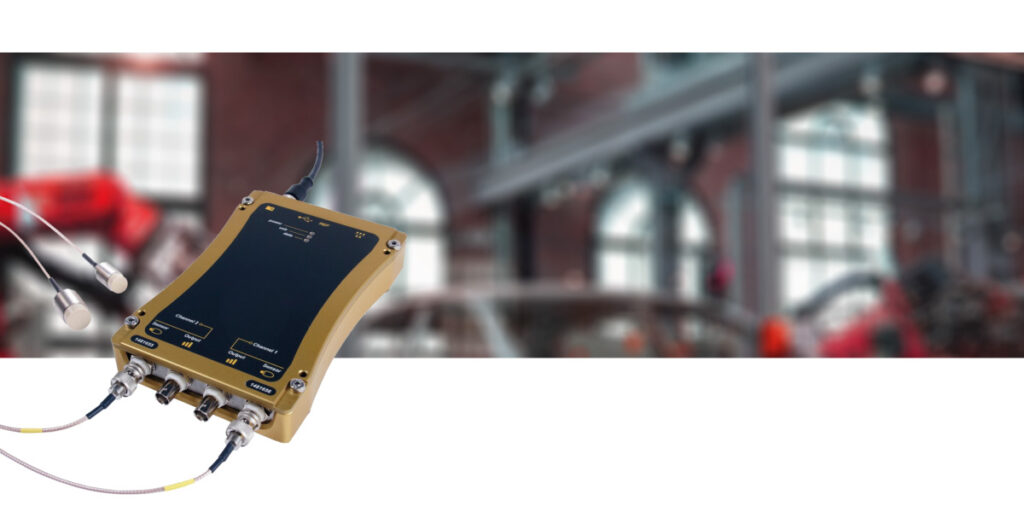

Position and speed of a lift

Position and speed of a lift

The GIANT-4

In 2001, 70 draw wire sensors from AK Industries were installed on the “GIANT 4”, the boat that was used to refloat the nuclear submarine “KOURSK” that weighed no less than 13 500 tons !

Giant 4 (Copyright 2008 ©Huisman Equipment B.V.)

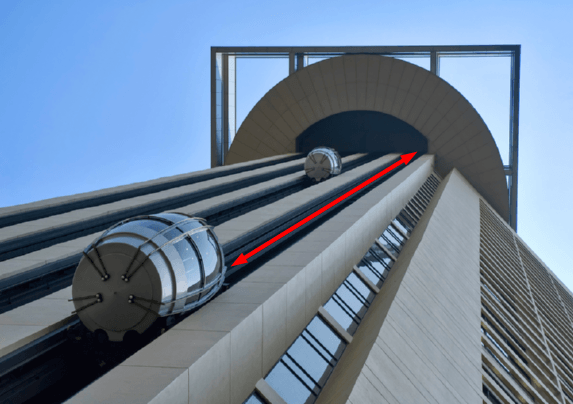

The Bacalan Bridge

More recently, in 2013, four 50m draw wire sensors were installed on the 4 pillars of the Bacalan bridge in Bordeaux in order to control the raising and lowering of the 48 m long platform, which crosses the Garonne.

The Bacalan Bridge (©Communauté Urbaine de Bordeaux)

The CERN

Installation of 30 LVDT sensors in the CERN in Geneva for the Large Hadron Collider (LHC): the most powerful particle accelerator in the world to validate physical theories.

Large Hadron Collider (©CERN)

Miscellaneous

(Draw wire Sensors)

- Woodworking machines (positioning control of a fixed blade with respect to a fixed blade)

- Geothermal drilling and boring machine (large measurement range sensors)

- On a hydroelectric dam to control gate opening

- Elevators

- Extruder control

- Fatigue test on airplane wing

- Positioning control of cutters on public works machine

- Positioning of glazing bead saw or press

- Several military applications (top secret)

- Raising a floor of a house (Canada)

Mechanical subcontracting

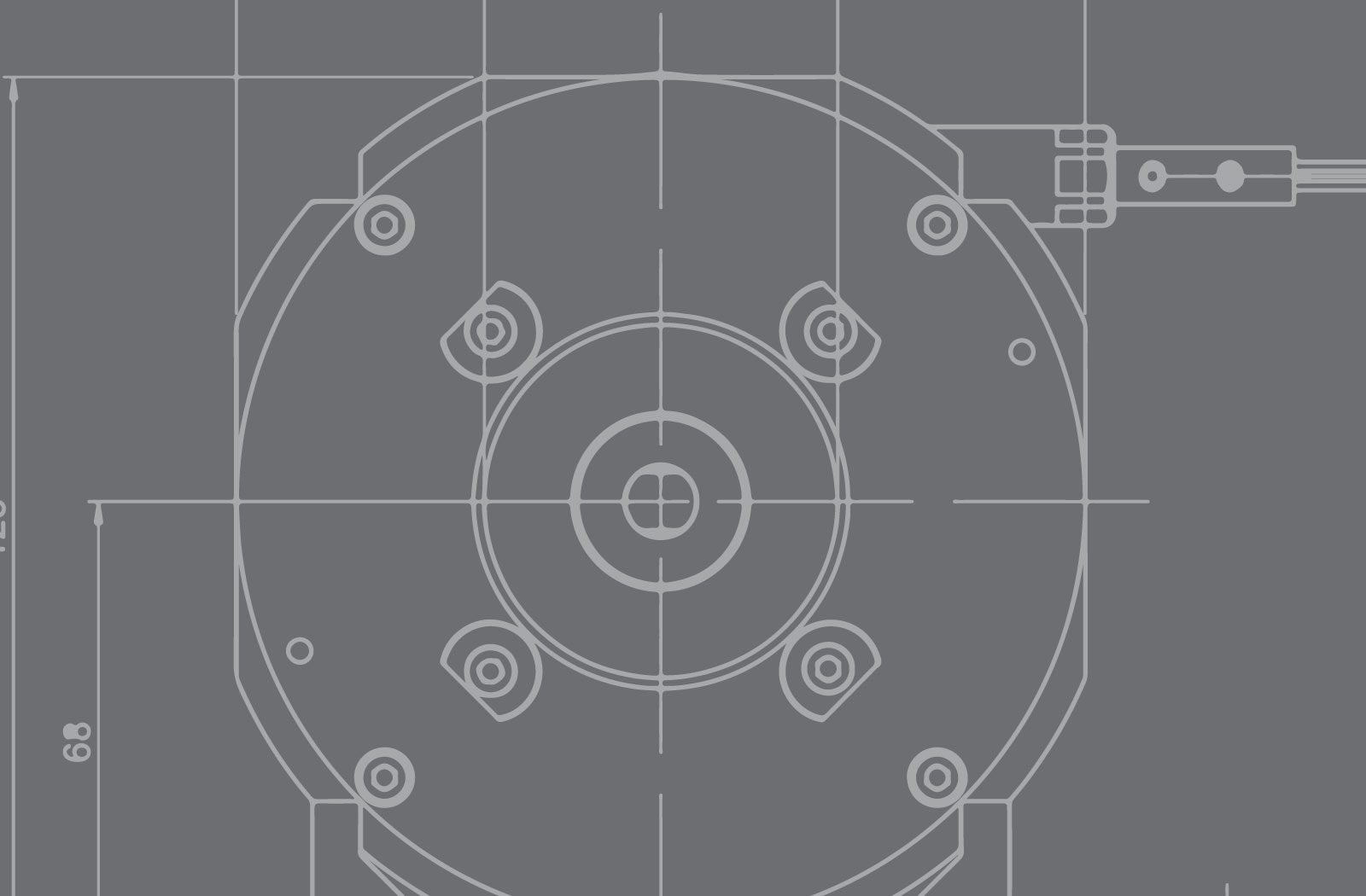

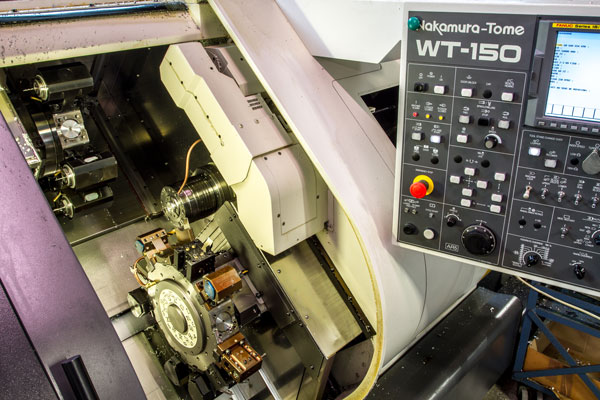

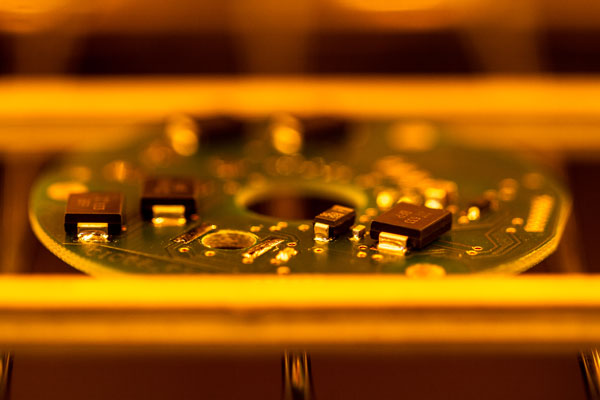

We offer our competencies in such areas as machining, assembly of sub-assemblies and electronic integration.

Our machinery is adapted to your needs for small and medium-sized series (1 to 5000 parts), in materials such as steel, stainless steel, aluminum, nickel, brass or even plastic.

The production plant consists of

- One automatic sliding headstock lathe

- One Multitasking CNC lathe

- One 5-axis CNC lathe

- One 4-axis CNC lathe

- One 2-axis CNC lathe

- One 5-axis-milling machine

- Two 3-axis-milling machines

- One Electrical Discharge Machine

- One gear hobbing machine

Service & Repair

We are sorry to learn that you have a product that is in need of repair.

If this is the case, please rest assured, dear customers, that we will do our best to satisfy you and send you back the sensor as soon as possible (the average repair time is one week).

Contact

AK Industries

ZA DU REITWEG

67440 THAL-MARMOUTIER

FRANCE

+33(0)3.88.02.09.02

+33 (0)3.88.02.09.03